Constant attention to the environment and health has led to an increasingly rapid evolution of sustainable building. In the construction sector, a new approach is emerging that, from design to construction, looks to sustainability as an objective to be achieved, from the use of materials, to construction techniques, to energy efficiency.

The transition to sustainable construction is no longer a choice but a necessity to improve the quality of life of citizens, reduce energy consumption, increase the value of homes, reduce emissions and reduce environmental impact. Today particular attention is paid to the entire life of the building product: from the procurement of raw materials to the production processes of materials, to the disposal of goods, to the recovery and recyclability of materials.

However, the concept of sustainable building is not new but was developed as early as 1970 in response to the energy crisis and the growing concerns of citizens about the environment. The process launched almost half a century ago continues today combining the needs and the evolution of the building, with respect for the environment, the territory and human health.

Particularly interesting is the project developed by Catalyst, a Florentine start-up that pursues the principles of sustainable architecture, through the recycling and re-use of materials deriving from the demolition of old buildings. The debris is collected on site and, through an innovative production system, transformed into new bricks to be reused immediately for new buildings. A perfect example of a circular economy that promotes energy savings and avoids CO2 emissions from processing and transport.

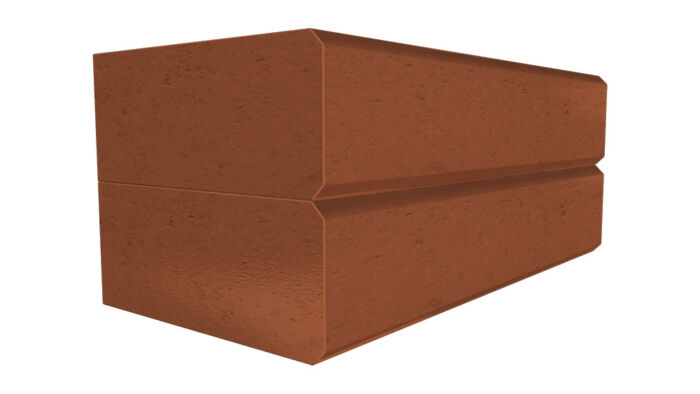

Catalyst provides a range of products and services summarized in three macro areas. It starts with RIBLOCK, or BLOCK cycle, a highly resistant brick made by compressing the demolition debris in special molds, which are carefully selected and mixed before cold pressing which transforms them into new building materials. The bricks thus produced allow a considerable saving of bricks, cements and mortars, not to mention that they considerably reduce the quantity of waste and CO2 emission.

The same recycling methods for inert materials developed for the Ri-Block are used to recycle Carrara marble processing scraps. Excavation dust from ongoing work in the Apuane quarries is also pressed into the moulds. The result is a beautiful white brick that can be left exposed for architectural purposes or used for ordinary load-bearing and curtain walls instead of the usual fired clay bricks. This all saves energy and produces less CO2.

With the same patented mixtures of materials, compressed in a suitable mould and handled by a specific machine, the product is formed into a particular shape fitted with ducts for the insertion of systems, and features 2 different exposed sides. The resulting walls have 2 finished sides, inside and out, obtaining a new, easier-to-use and quick construction system.

“Catalyst products and designs start from a cultural approach that identifies itself with sustainable building, energy savings and recovering debris that would otherwise be classified as waste – the manager says – Catalyst is based on ecological principles and the sustainable development concept by considering the “man-nature-function” concept in its broadest sense”.