Developing a new process for the recovery of high-value materials and metals from end-of-life mobile phones with a view to the circular economy. This is the aim of the PORTENT project, co-financed by the Lazio Region with about 140,000 euros through the European Regional Development Fund and coordinated by the ENEA Laboratory ‘Technologies for the Reuse, Recycling, Recovery and Valorisation of Waste and Materials‘. “The amount of waste from electrical and electronic equipment is growing, mainly due to increasingly shorter technical obsolescence times. This phenomenon could generate serious management problems linked to the presence of metals and harmful substances that pose a real risk to human health and the environment,” explains Danilo Fontana, ENEA researcher and PORTENT project manager.

The year 2020 saw a significant growth in the collection of this type of waste: at national level it exceeded 78 thousand tonnes (+7.68% compared to 2019), while in the Lazio Region the share was about 6 thousand tonnes with a significant leap forward compared to the 2.4 thousand tonnes of the previous year. Among this waste, mobile phones are certainly the electronic devices of greatest interest for the valuable and strategic materials they contain.

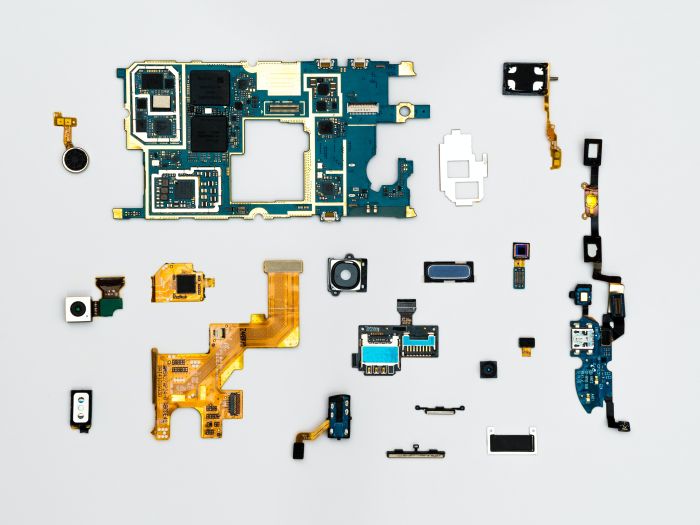

“The tendency of Italian recycling companies is to stop at the simplest but less profitable treatment and recycling stages, such as the shredding and separation of plastics and metals, leaving foreign operators the advantage of recovering the ‘noble’ part of the waste, in particular electronic boards rich in metals such as gold, silver, palladium and copper. Starting from our expertise in this sector, in synergy with the Sapienza University of Rome, we want to develop an innovative process for recovering materials from disused mobile phones to complete the supply chain, which currently stops at trading the stocks of separated materials abroad,” Mr Fontana stresses.

A tonne of end-of-life electronic phone cards contains on average 276 g of gold, 345 g of silver, 132 kg of copper; if other components such as magnets and integrated antennas are taken into account, the list grows longer with rare earths (such as neodymium, praseodymium and dysprosium) reaching up to 2.7 kg per tonne of smartphone.

“Thanks to current technologies, it is possible to recycle more than 96% of these electronic devices, recovering significant quantities of precious metals with high degrees of purity. This would make it possible to avoid the depletion of natural resources and the supply of some of these critical raw materials, which are mainly found in politically unstable countries,” continues Mr Fontana.

For the PORTENT project, ENEA researchers will use hydrometallurgical technologies (alternatives to pyrometallurgy) because they guarantee low energy consumption (operating at room temperature), low emissions, modularity of the plants and flexibility of use. These are all features that enable an easy up-scaling process and easy replicability in industrial contexts, without neglecting the social acceptability of this type of plant at local level. And that’s not all. “Hydrometallurgy is a technique that is particularly suitable for the separation and selective purification of elements with high added value, even in matrices with low concentrations of metals. Whereas pyrometallurgy, in order to be sustainable, has to process huge quantities of material that is often not available in a single national area, but has to be found in geographical areas far away from the plants themselves,” adds Mr Fontana.

Once the project is completed, the results of the research will be transferred to the entrepreneurial fabric both for the technological innovation of industrial processes and for the development of new qualified professional skills. “The aim is to contribute to the growth of the local and national economy and to reduce the environmental impact of this type of waste, which, thanks to the recovery of the materials it contains, will become a source of secondary raw materials for new technological products,” concludes Mr Fontana.