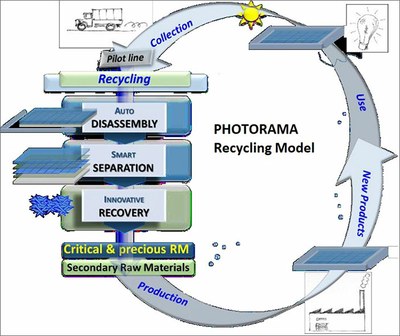

Developing innovative technological solutions to maximise the recovery of raw materials from end-of-life photovoltaic panels and creating a European industrial supply chain to produce new ones in a circular economy. This is the objective of the EU project PHOTORAMA, funded by the Horizon2020 programme with EUR 8.4 million, which involves 13 research institutes and companies, including ENEA and Enel Green Power (EGP) for Italy and the French CEA in the role of coordinator.

“The technology we will develop through this project will enable us to recover almost 100 per cent of the materials from end-of-life panels, with a degree of purity never achieved before. There is no industrial process in the world today that is capable of doing this. Achieving this goal would help the entire solar industry take a huge step forward from current recycling standards and, above all, reduce Europe’s dependence on imports of critical raw materials,” explains Massimo Izzi, ENEA’s PHOTORAMA project manager and researcher at the Engineering Laboratory for the Photovoltaic Industry.

ENEA research will focus on the eco-design of photovoltaic modules in order to develop a production technique that makes the panel easily recyclable in all its components. Enel Green Power will evaluate the best technology for recycling photovoltaic modules and validate the use – in the manufacture of photovoltaic modules – of components produced with recovered raw materials, increasing the circularity of the modules of the 3SUN factory in Catania.

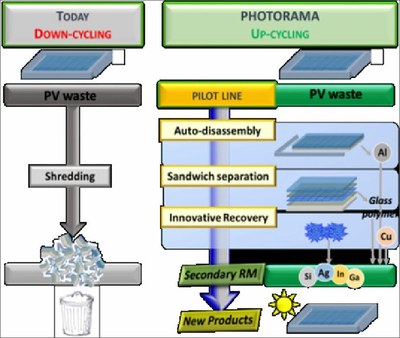

The new industrial line will use an innovative delamination technology that is able to efficiently separate solar cells from the glass sheet, while innovative physico-chemical processes will allow all materials to be recovered without resorting to the current inefficient photovoltaic module shredding techniques in which cells, the valuable part of the module, end up in a recovery chain of low economic value (so-called down-cycling). The new technological process will result in “up-cycling” by recovering high-value materials (such as aluminium from the frame and glass and polymers from the sheets) and metals from the solar cell layer (critical such as silicon, indium and gallium, and precious such as silver).

“The new recovery and recycling technology will thus enable the implementation of a relevant economic business case through a high recovery rate of more than 98% of photovoltaic materials at the end of their industrial life cycle. This is currently the highest known recycling rate in the world,” concludes Izzi.

Nel rapporto “End of Life: Solar Photovoltaic Panels” dell’International Renewable Energy Agency (IRENA) si prevede che si passerà da 10 milioni di tonnellate nel 2030, a circa 78 milioni di tonnellate nel 2050 di pannelli disponibili, con i quali sarebbe possibile realizzare oltre 2 miliardi di nuovi pannelli e generare un giro di affari di 15 miliardi di dollari. La gestione del futuro dei moduli fotovoltaici, quindi, può diventare un’opportunità in grado di dare vita a un giro di affari, legato ai componenti recuperabili, di 450 milioni di dollari al 2030.

Inoltre, si prevede che la crescita della produzione di elettricità solare raggiungerà una capacità cumulativa di 2.840 GW entro il 2030 e 8.519 GW entro il 2050, che equivale a diciotto volte la capacità globale del 2018. Sebbene i pannelli fotovoltaici forniscano una generazione di energia a emissioni zero per una durata complessiva di circa 25-30 anni, è fondamentale garantire sempre di più prodotti sostenibili e a basso impatto ambientale per sostenere la transizione ecologica prevista dal New Green Deal europeo.